SANWA IRON (THAILAND) CO.,LTD

SANWA IRON (THAILAND) CO.,LTD

Fastener-class coating material is a waterborne/VOC – compliant, resin-bonded thermally cured, single film, dry lubricant. It is primarily formulated for use on fasteners to prevent corrosion and facilitate make-up torque.

Provides lubrication with extra corrosion protection. Xylan 1070 is used to coat large studs, nuts, flanges and related hardware for sub-sea and splash-zone service. Because of its predictable low-friction properties, less “make-up” torque is required to produce the specified tension. During assemble, clamp loads are increased; “scatter” is reduced. In fact, the frictional characteristics are the most predictable of any lubricant, coating or plating used on bolting. The low-friction properties also reduce “break-out” torque, which allows removal of bolting with a wrench instead of a blowtorch

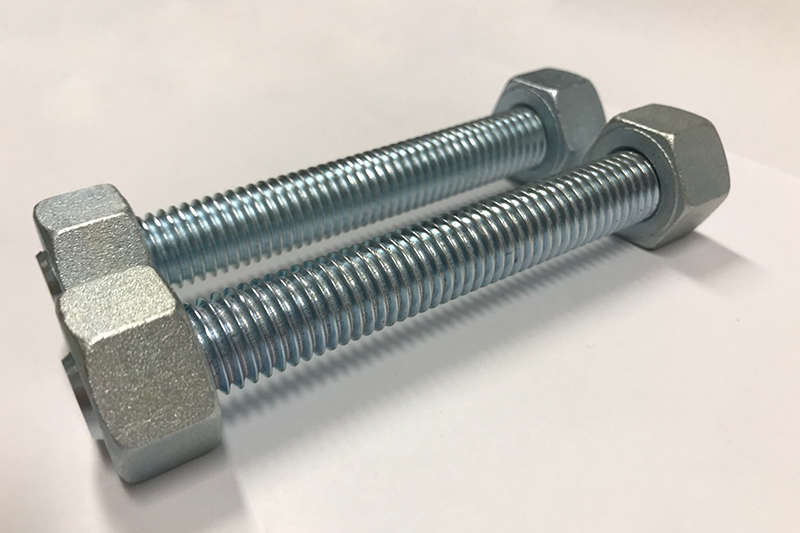

The hot-dip galvanizing process consists of parts being immersed in molten zinc for a sufficient time to allow a metallurgical reaction between iron from the steel surface and the molten zinc, Specification according to ASTM A153

Zinc Plate

For other coating please contact us to clarify.